[/lommy power]

Non-stop tracking – without running low on battery

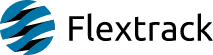

Lommy Power is a small, unique and patented GPS tracking device that operates without the use of a built-in battery. Instead, the tracking device draws power from the battery of the machine. When Lommy Power is connected to your machinery, it is on and ready to transmit real-time data.

Monitor your entire fleet of machinery and equipment in real time

Track the current position, activity and movement of your machinery. GPS technology gives you an accurate position (within a few metres).

Intelligent automation

Lommy Power never exhausts the machinery battery due to intelligent automation:

- When a machine is turned on and its battery charges, Lommy Power transmits data every 2 minutes.

- When a machine is turned off, Lommy Power only transmits data every

24 hours. - Lommy Power also has a motion sensor to detect if a machine is being moved while turned off. If this is the case, Lommy Power will transmit data every 2 minutes to trace the movement of the machine.

Key features:

- Monitoring of the machine’s operating hours

- Accurate GPS tracking in case of theft

- Suitable for both 12V and 24V systems

- Low power consumption

- Easy installation

- Small in size (54x44x19 mm): Fits into machinery of all sizes

- IP65 waterproof: Built to last in harsh environments, such as construction sites

- Set up custom alarms and geofence

- 3rd wire: Track activity of auxiliary equipment

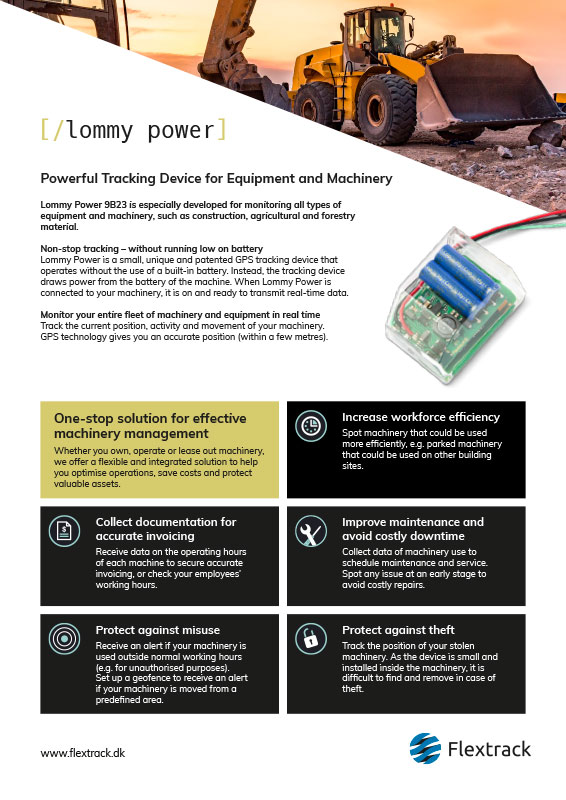

One-stop solution for effective machinery management

Whether you own, operate or lease out machinery, we offer a flexible and integrated solution to help you optimise operations, save costs and protect valuable assets.

Increase workforce efficiency

Spot machinery that could be used more efficiently, e.g. parked machinery that could be used on other building sites.

Collect documentation for accurate invoicing

Receive data on the operating hours of each machine to secure accurate invoicing, or check your employees’ working hours.

Improve maintenance and avoid costly downtime

Collect data of machinery use to schedule maintenance and service. Spot any issue at an early stage to avoid costly repairs.

Protect against misuse

Receive an alert if your machinery is used outside normal working hours (e.g. for unauthorised purposes). Set up a geofence to receive an alert if your machinery is moved from a predefined area.

Protect against theft

Track the position of your stolen machinery. As the device is small and installed inside the machinery, it is difficult to find and remove in case of theft.

[/optimise operations, save costs and protect valuable assets]

Monitor your machinery on various platforms – 24/7

Use our monitoring system or your own system to keep track of your entire fleet via phone, tablet or computer.

TrackEye

Basic, easy to use platform incl. real-time map, historical data and custom alarms.

LommyFleet

Complete fleet management platform incl. real-time map with historical trails, custom alarms, geofence, report generator and maintenance planning.

White Label

Customised, branded platform, based on our systems.

System integration (API)

Use your own system. We will provide open source software and API.

Technical Data – Lommy Power 9B23

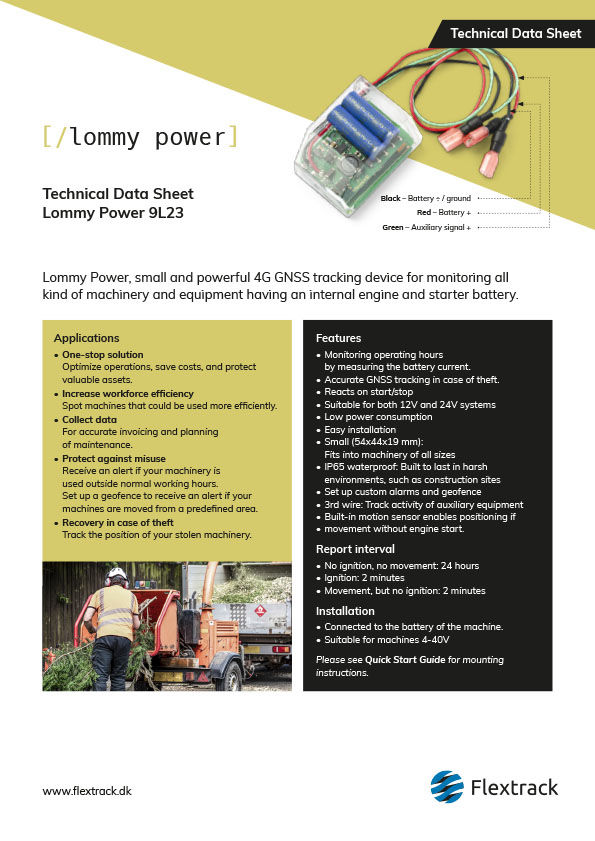

Features

Features

-

Monitoring operating hours

by measuring the battery current. -

Accurate GNSS tracking in case of theft.

-

Reacts on start/stop

-

Suitable for both 12V and 24V systems

-

Low power consumption

-

Easy installation

-

Small (54x44x19 mm): Fits into machinery of all sizes

-

IP65 waterproof: Built to last in harsh environments, such as construction sites

-

Set up custom alarms and geofence

-

3rd wire: Track activity of auxiliary equipment

-

Built-in motion sensor enables positioning if movement without engine start.

Report interval

- No ignition, no movement: 24 hours

- Ignition: 2 minutes

- Movement, but no ignition: 2 minutes

Installation

- Connected to the battery of the machine.

- Suitable for machines 5-40V

Specifications

Specifications

Positioning and communication:

-

FDD LTE Cat M1 bands B3/B8/B20

-

GSM: Quad band 2G – 850/900/1800/1900 MHz

-

GNSS: GPS, GLONASS, GALILEO, BEIDOU, QZSS

-

SBAS: WAAS, EGNOS, MSAS, GAGAN

-

Assisted GNSS

-

33 Tracking channels & 99 Acquisition channels & 210 PRN channels

Tracking sensitivity: -166 dBM -

Data protocol: UDP, SMS

Interface:

- Sensors: 3 axis G-sensor

- Internal memory: 2 MB flash

- Antennas, Internal:

GNSS

LTE/GSM

Physical:

- Weight: 42g

- Measurement: 54x44x19mm

- Protection: IP65

- Temp. range: -30 to +60 C°

The intelligent 4G + 2G technology

- Ensures optimal connection

- Primarily uses 4G if available

- Switches seamlessly to 2G in remote areas

- Connects quickly when changing networks

- Connects quickly when changing countries

Compliance

- CE, E pending, RoHS and WEE

Server and data security:

- ISAE3402 certified (referring to ISO 27002)

Quick Start Guide

Quick Start Guide

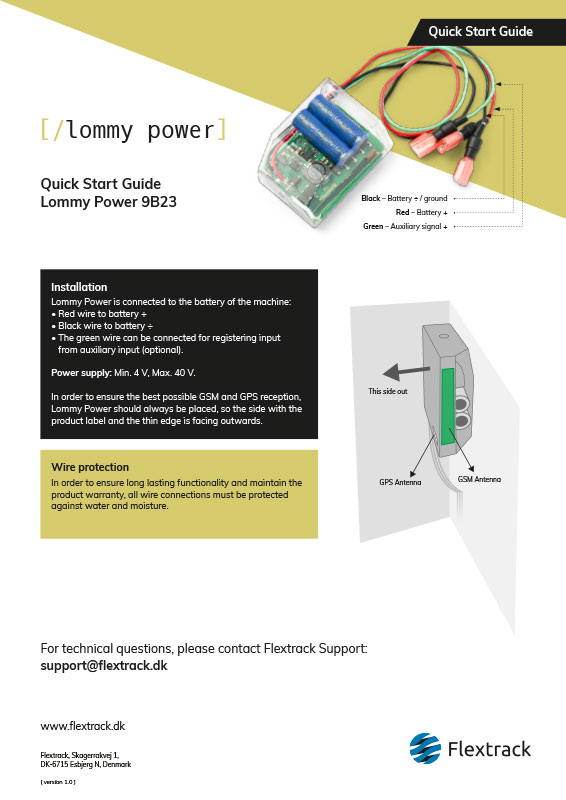

Installation

Lommy Power is connected to the battery of the machine:

- Red wire to battery +

- Black wire to battery ÷

- The green wire can be connected for registering input from auxiliary input (optional).

Power supply: Min. 5 V, Max. 40 V.

In order to ensure the best possible GSM and GPS reception, Lommy Power should always be placed, so the side with the product label and the thin edge is facing outwards.

Wire protection

In order to ensure long lasting functionality and maintain the product warranty, all wire connections must be protected against water and moisture.

Testing

- When Lommy Power is active, the green LED will be on.

- When connected to a battery with sufficient power (min. 5 V), the red LED will be on.

- When a signal is registered on the auxiliary input, the yellow LED will be on.

Function

By measuring the battery current, Lommy Power reacts on engine start/stop – both for 12V and 24V systems.

The built-in motion sensor also enables Lommy Power to react and report when the machine is moved without engine start.

Reporting

Depending on the measured battery current and the auxiliary signal, Lommy Power will switch between active and idle mode.

- Report interval when in active mode (the machine is running, or auxiliary signal is registered): Every 2 minutes.

- Report interval when in idle mode (the machine is stopped, and no auxiliary signal is registered): Every 24 hours.

- Report interval when in idle mode, if movement is detected: Every 2 minutes.

Included in every report, an hour-counter for both active mode and auxiliary input (5 – 40 V), are sent to the server.

Alarms:

- Triggered by signal on auxiliary input

- Triggered by movement when the machine is turned off.